What Industries Are the Application Scenarios of Carbon Film Resistors Included In?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors, carbon film resistors are widely used due to their unique properties and advantages. This blog post will explore the definition of carbon film resistors, their importance in electronic circuits, and the diverse industries that utilize them.

A. Definition of Carbon Film Resistors

Carbon film resistors are passive electronic components that limit the flow of electric current in a circuit. They are made by depositing a thin layer of carbon on a ceramic substrate, which is then cut into a specific shape to create resistance. The resistance value is determined by the thickness and length of the carbon film, making these resistors versatile for various applications.

B. Importance of Resistors in Electronic Circuits

Resistors are fundamental components in electronic circuits, serving multiple purposes such as voltage division, current limiting, and signal conditioning. They ensure that electronic devices operate efficiently and safely by preventing excessive current flow that could damage sensitive components. Carbon film resistors, in particular, are favored for their stability, reliability, and low noise characteristics.

C. Overview of the Paper's Focus on Industries

This blog post will delve into the key industries that utilize carbon film resistors, highlighting their applications and the significance of these resistors in each sector. From consumer electronics to renewable energy, carbon film resistors play a vital role in enhancing the performance and reliability of various devices.

II. Understanding Carbon Film Resistors

A. Composition and Manufacturing Process

1. Materials Used

Carbon film resistors are primarily composed of carbon, which is known for its excellent conductivity and stability. The carbon is mixed with a binder material to form a paste, which is then applied to a ceramic substrate. The choice of materials is crucial, as it directly impacts the resistor's performance and durability.

2. Production Techniques

The manufacturing process involves several steps, including the deposition of the carbon film, cutting it into the desired shape, and applying protective coatings. Advanced techniques such as laser trimming are often used to achieve precise resistance values, ensuring that the resistors meet stringent specifications.

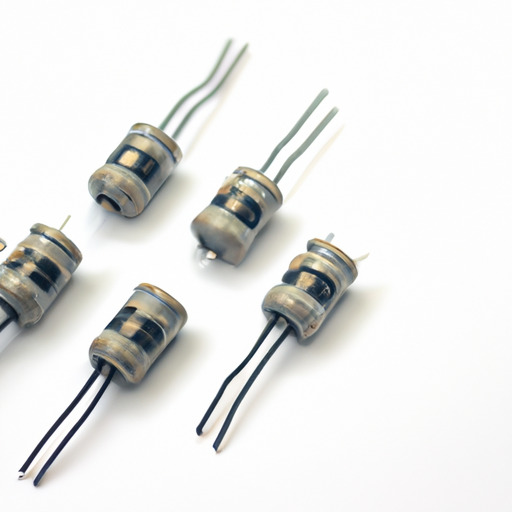

B. Characteristics and Advantages

1. Stability and Reliability

One of the key advantages of carbon film resistors is their stability over a wide range of temperatures and environmental conditions. They exhibit minimal drift in resistance values, making them suitable for applications that require consistent performance.

2. Temperature Coefficient

Carbon film resistors have a low temperature coefficient, meaning their resistance changes very little with temperature fluctuations. This characteristic is essential in applications where temperature variations are common, ensuring reliable operation.

3. Noise Performance

These resistors are known for their low noise performance, which is critical in audio and precision measurement applications. The reduced noise levels contribute to clearer signals and improved overall performance of electronic devices.

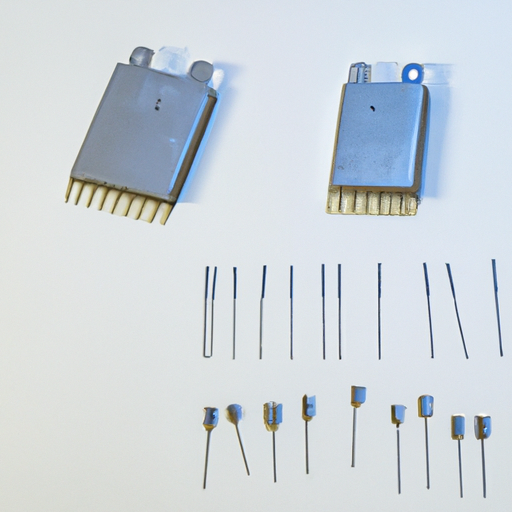

C. Comparison with Other Types of Resistors

1. Metal Film Resistors

While metal film resistors offer higher precision and lower noise levels, carbon film resistors are often more cost-effective and suitable for a broader range of applications. They strike a balance between performance and affordability.

2. Wirewound Resistors

Wirewound resistors are known for their high power handling capabilities but can be bulkier and less stable than carbon film resistors. In contrast, carbon film resistors are compact and provide adequate performance for most applications.

III. Key Industries Utilizing Carbon Film Resistors

A. Consumer Electronics

1. Applications in Audio Equipment

In the consumer electronics sector, carbon film resistors are commonly used in audio equipment such as amplifiers and mixers. Their low noise performance ensures high-quality sound reproduction, making them a preferred choice for audiophiles.

2. Use in Home Appliances

Carbon film resistors are also found in various home appliances, including washing machines, microwaves, and refrigerators. They help regulate power and ensure the safe operation of these devices.

3. Role in Mobile Devices

With the rise of smartphones and tablets, carbon film resistors play a crucial role in mobile devices. They are used in power management circuits, signal processing, and various other applications that require compact and reliable components.

B. Automotive Industry

1. Integration in Engine Control Units (ECUs)

In the automotive industry, carbon film resistors are integrated into engine control units (ECUs) to monitor and control engine performance. Their stability and reliability are essential for ensuring optimal engine operation.

2. Use in Infotainment Systems

Carbon film resistors are also utilized in infotainment systems, where they help manage audio signals and control various functions. Their low noise characteristics contribute to a better user experience.

3. Safety and Sensor Applications

In modern vehicles, safety systems rely on accurate sensor readings. Carbon film resistors are used in various sensors to ensure precise measurements, enhancing overall vehicle safety.

C. Telecommunications

1. Role in Signal Processing Equipment

In telecommunications, carbon film resistors are critical components in signal processing equipment. They help maintain signal integrity and reduce noise, ensuring clear communication.

2. Use in Networking Devices

Networking devices such as routers and switches also utilize carbon film resistors. They play a vital role in managing power and signal levels, contributing to the overall performance of the network.

3. Applications in Mobile Communication

With the increasing demand for mobile communication, carbon film resistors are essential in mobile devices and infrastructure. They help optimize signal quality and ensure reliable connectivity.

D. Medical Devices

1. Importance in Diagnostic Equipment

In the medical field, carbon film resistors are used in diagnostic equipment such as ECG machines and blood pressure monitors. Their stability and accuracy are crucial for obtaining reliable measurements.

2. Use in Monitoring Devices

Carbon film resistors are also found in various monitoring devices, including wearable health monitors. They help ensure accurate readings, contributing to better patient care.

3. Applications in Imaging Systems

In medical imaging systems, carbon film resistors play a role in signal processing and control circuits, ensuring high-quality images for accurate diagnosis.

E. Industrial Automation

1. Role in Control Systems

In industrial automation, carbon film resistors are used in control systems to manage processes and ensure efficient operation. Their reliability is essential for maintaining productivity.

2. Use in Robotics

Carbon film resistors are also found in robotics applications, where they help control motors and sensors. Their compact size and stability make them ideal for use in robotic systems.

3. Applications in Process Control

In process control applications, carbon film resistors are used to monitor and regulate various parameters, ensuring optimal performance and safety.

F. Renewable Energy

1. Use in Solar Inverters

As the demand for renewable energy grows, carbon film resistors are increasingly used in solar inverters. They help manage power conversion and ensure efficient energy utilization.

2. Applications in Wind Energy Systems

In wind energy systems, carbon film resistors are utilized in control circuits to optimize performance and ensure reliable operation.

3. Role in Energy Storage Solutions

Carbon film resistors are also found in energy storage solutions, where they help manage power flow and ensure efficient energy use.

IV. Emerging Trends and Future Applications

A. Advancements in Technology

1. Miniaturization and Integration

As technology advances, there is a growing trend towards miniaturization and integration of electronic components. Carbon film resistors are adapting to these changes, becoming smaller and more efficient to meet the demands of modern devices.

2. Smart Devices and IoT

The rise of smart devices and the Internet of Things (IoT) presents new opportunities for carbon film resistors. Their reliability and performance make them ideal for use in connected devices that require precise control and monitoring.

B. Sustainability and Environmental Considerations

1. Eco-friendly Manufacturing Processes

With increasing awareness of environmental issues, manufacturers are exploring eco-friendly processes for producing carbon film resistors. This shift towards sustainability is likely to shape the future of the industry.

2. Role in Energy Efficiency

Carbon film resistors contribute to energy efficiency in electronic devices, making them an essential component in the push for greener technology.

C. Potential New Markets

1. Electric Vehicles

The growing electric vehicle market presents new opportunities for carbon film resistors. They will play a crucial role in power management and control systems, ensuring efficient operation.

2. Smart Grids

As smart grids become more prevalent, carbon film resistors will be essential in managing power distribution and ensuring reliable energy supply.

3. Wearable Technology

The rise of wearable technology also offers new applications for carbon film resistors. Their compact size and reliability make them ideal for use in health monitoring devices and fitness trackers.

V. Conclusion

A. Summary of Key Points

Carbon film resistors are versatile components that play a vital role in various industries, including consumer electronics, automotive, telecommunications, medical devices, industrial automation, and renewable energy. Their stability, reliability, and low noise performance make them a preferred choice for many applications.

B. The Ongoing Relevance of Carbon Film Resistors

As technology continues to evolve, carbon film resistors remain relevant due to their adaptability and performance. They are essential in meeting the demands of modern electronic devices and systems.

C. Future Outlook for the Industry and Applications

The future of carbon film resistors looks promising, with emerging trends such as miniaturization, sustainability, and new market opportunities driving innovation. As industries continue to evolve, carbon film resistors will play a crucial role in shaping the future of electronics.

VI. References

A. Academic Journals

- Various academic journals on electronics and materials science.

B. Industry Reports

- Reports from industry analysts on the trends and forecasts for the resistor market.

C. Manufacturer Specifications and White Papers

- Specifications and white papers from leading manufacturers of carbon film resistors.

---

This blog post provides a comprehensive overview of the industries that utilize carbon film resistors, highlighting their applications, characteristics, and future trends. By understanding the significance of these components, we can appreciate their role in the ever-evolving world of electronics.